Product Name: BOPP Film

Our bopp thermal lamination film is smoothcoating with high subsequent adhesion.

Specifications :

Color: Clear And White

Material: PP

Appearance: Transparent

Style: Film

Packaging Terms : Standard

Quantity Required : 1 Twenty-Foot Container

Shipping Terms : FOB Or CIF

Looking for suppliers from : Worldwide

Good Resistance Bopp Thermal Lamination Films

1.production introduction

BOPP Film (Biaxially Oriented Polypropylene Films) are produced by stretching polypropylene film, in both lengthways and transverse direction. BOPP Film is used in vast variety of applications comprising packaging, labeling and lamination. We supply Customizable Logo/Size/Color with super service,Sgs Certified bopp thermal lamination films . The Free radical UV curing technology.

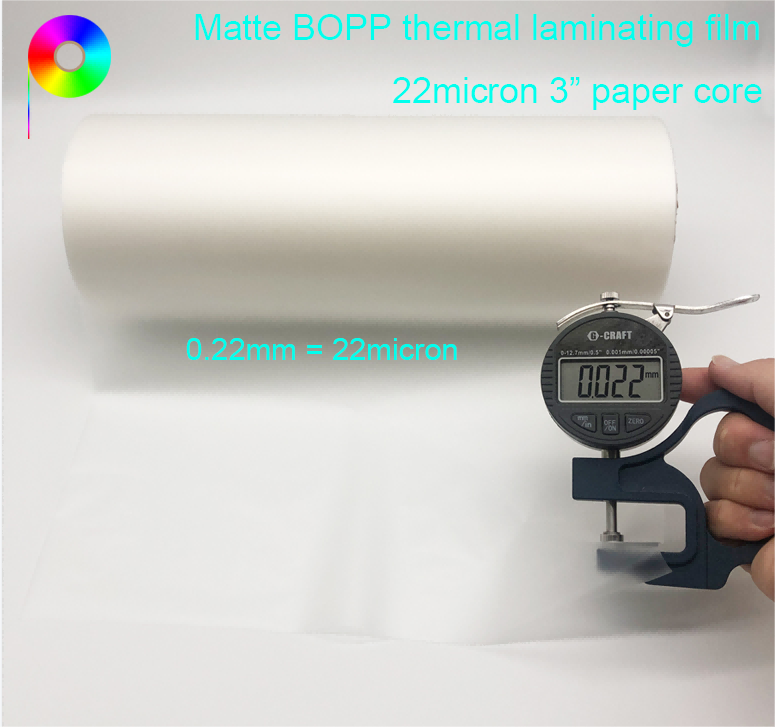

2. ![]() Product Parameter(Specification)of bopp thermal lamination films

Product Parameter(Specification)of bopp thermal lamination films

| Specification | BOPP-17 glossy |

Bopp-20 glossy |

BOPP-24 glossy |

BOPP-30 glossy |

BOPP-17 matte |

BOPP-20 matte |

BOPP-23 matte |

BOPP-27 matte |

BOPP-30 matte |

||

| Thickness (U) |

Total (micron) |

17 | 20 | 24 | 30 | 17 | 20 | 23 | 27 | 30 | |

| BOPP (micron) |

12 | 12 | 12 | 18 | 12 | 12 | 15 | 15 | 18 | ||

| EVA (micron) |

5 | 8 | 12 | 12 | 5 | 8 | 8 | 12 | 12 | ||

| Weight | M2/kg | 63.94 | 54.23 | 45.4 | 36.15 | 64.5 | 55.4 | 47.03 | 44.13 | 37.37 | |

| g/m2 | 15.64 | 18.43 | 22.2 | 27.66 | 15.5 | 18.36 | 21.26 | 24.18 | 26.76 | ||

| Tension | BOPP side ≥38dyne, Eva side≥52 dyne | ||||||||||

| Corona treatment |

Ae | B | AB(double sides) | ||||||||

| Width | 200;390;440;540;590;780;880;1330;1800 ... ±3mm Upon customer's dequire |

||||||||||

| Lengthe | 2000-4300M±5% | ||||||||||

| Paper core |

Inside paper core 25.4mm 76mm | ||||||||||

| Joint |

≤2

|

||||||||||

3. Product details;

good resistence and tension

BOPP film is easily amenable to the following types of processing: printing, cutting, lamination, sealing.

stable quality with different thickness

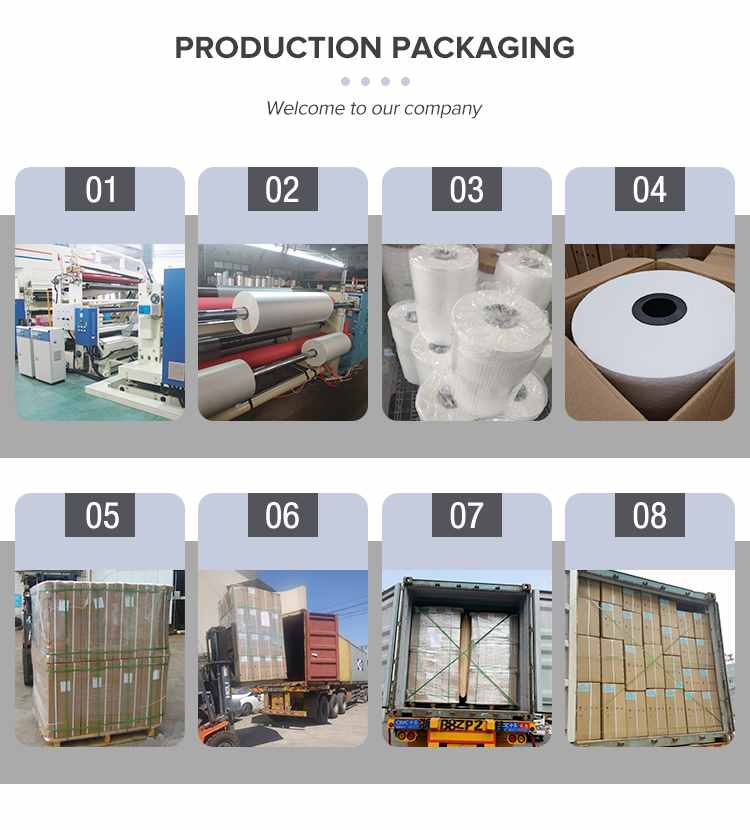

4.delivery :shipping and service :

Custom Printed Packaging,standard and custom sizes available,Guaranteed Top Quality & Service.and Factory direct shipment.

5:FAQ:

1.What are the advantages of BOPP Films?

Shelf life extension: Among all other commonly used plastic films, BOPP films provides excellent moisture barrier & its metallized variant provides better oxygen barrier to product. Both these properties of BOPP films play a key role in food packaging to extend the shelf life of products & thus reduce food waste.

Product Quality: Apart from barrier properties, BOPP film provides consistent and excellent seal integrity because of narrow gauge spread. Good heat seal strength, lower seal initiation temperature, broad sealing window and good machinability further benefits into food packaging industry for protecting food quality.

Sustainability: BOPP film has a relatively low carbon footprint as compared to other plastic films substrate such as polyester. After cellulose film, BOPP Film is the second most preferred substrate for its ecofriendly nature in flexible food packaging. Because of its low melting point, it requires lower energy to convert from one form to other. Reprocessed granules of BOPP resin are widely used to manufacture injection molded parts, household items like sitting mats, chair, table, automobile spares etc.

Aesthetic / Graphics: Excellent transparency in clear BOPP films allows providing high level of aesthetic appeal to product packaging. Half tone printing jobs with multi color printing are also carried out with ease on this film for high quality graphics. In white opaque film variant, excellent gloss, high opacity and superb whiteness provides an attractive look to product packaging. Metalized film variety gives superior metallic appearance to stand out your product on the shelf. Because of good surface tension, post lamination operations like foil stamping, UV spot coating and embossing could be carried out to enhance aesthetic look of product packaging.

Density: It is a unique property that BOPP films has among all other commonly used flexible packaging films. Low density results into more yield during conversion and thus supports less plastic consumption concept per product. Low density results into less weight per roll for the same length of other plastic film which provides ease of material handling.

2.What are the variants of best quality BOPP offered by Dupack Polyfilms?

Metallized Film

It is used for high barrier Flexible, packaging, metallic yarn, sequins for textiles, decorative, etc. Metallized BOPP films are used for flexible packaging, gift wraps and decorative.

Heat-Sealable & Pearlized Films

These films are meant for advanced packaging, labeling and decorative wrap-ups of different products. Their custom thinness and transparent coating have turned these films among-st the premium picked choices by the companies seeking advanced packaging solutions.

There is a wide collection of Heat Sealable BOPP Film available, which fits perfect in the varied requirements of users. There are films that seal on low temperature heat. Films that are sealable from single side with heat are also available. Companies seeking for finest lamination films for advanced packaging of their products get a gigantic collection to choose from.

Some of the handpicked categories of these heat sealable lamination films include glossy films with high inability and high level stretchy power. Some of the usage examples of these films include packaging of teabag box, cigarette box, cassettes, CD bundle and many more. These films are thin but offer strong and sustainable packaging to the product they are wrapped upon.

Some of the major features that distinguish these packaging & lamination films from others include transparency and clarity flexible & highly stretchable, strong dimensional steadiness, aureole treatment on either or both sides of the film and they are waterproof, assuring safety to the products packed in them.

Tape & Textile Films

BOPP Tape Film is extensively used for self-adhesive tape applications. Flame treatment is preferred on such films to retain the surface treatment for longer periods. Textile BOPP film is also used for packaging of textile garments like shirts, sarees etc. Textile films are generally transparent in nature and printed in selective applications only. Packaging for bulky items like blanket etc requires high seal strength. Tape and textile films are generally treated on one side only.

To get premium and smart BOPP packaging solutions, Dupack Polyfilms can be the best choice as we bring you a wide series of custom designed quality packaging films.